An Update On weld preheat machine Secrets

You can flick through all the selection of welding equipment that’s available and choose the ones that you think will suit your needs the best. Exercise patience and stay prepared to schedule a few hours when beginning search for welding equipment particulars on the Internet. Therefore you must be sure that you have the right goal planned to ensure that you have the best equipment that could fit your needs.

The current is often as high as 12000 amps, which can be required for spot welding. Power supply equipment carries a transformer, generator, and alternator and inverter. Prepare beforehand a summary of things you want a quote for. There are a host of tools and accessories that you’d need being a welder. The possibility of preventing cracked seals or damaging the weld can be considerably decreased in TIG machines. Whether you might be an OEM or possibly a contract manufacturer, getting a competitive price for welding and fabrication services is vital.

With push button control panels, the machines are exceptionally accessible and several high-end models supply you with the option to easily adjust for repeatable weld cycles, start, and weld crater. Choose a manufacturer with a proven track record in manufacturing heavy industrial equipment by using latest along with the most advanced fabrication welding techniques. A single gauge gas regulator calculates the pressure inside the bottle. A twin gauge measures the flow rate of the gas along with all the pressure. As the technology is developing drastically, different types of machines have introduced in market each one has their own qualities.

Many eBay sellers sell a complete batch of tig cups for what you might buy just one your local welding supply store. This means you must think about factors like the kind of metal you’ll be welding, how thick it’s, the location where the weld is going to be, the roughness with the material and how much time you have got open to spend on your welding. Filler materials are also available in different materials for example magnesium and tungsten. All the same, you may be required to visit several sites online to generate your welding equipment decision for the best deal at the right price.

Also, the welding industry ought to be equipped with modern tools including welding electrodes, welding torches, welding consumables and welding guns and really should follow the proper welding system with appropriate welding technology. A regular old arc welder will only be used as a last resort like whenever your mig welder breaks, but you will need one anyway simply because used arc welders are very inexpensive and you just might need one. One in the benefits of this type of Welding Equipment is that you are able to use it on thicker sheets of metal, as well as surfaces which might be rougher and unsuitable for welding with oxyacetylene equipment. However, a transformer based welding structure is usually expensive but tend to assist in a variety of applications.

An Update On WHT machine Secrets

The current is often as high as 12000 amps, which can be required for spot welding. Power supply equipment carries a transformer, generator, and alternator and inverter. Prepare beforehand a summary of things you want a quote for. There are a host of tools and accessories that you’d need being a welder. The possibility of preventing cracked seals or damaging the weld can be considerably decreased in TIG machines. Whether you might be an OEM or possibly a contract manufacturer, getting a competitive price for welding and fabrication services is vital.

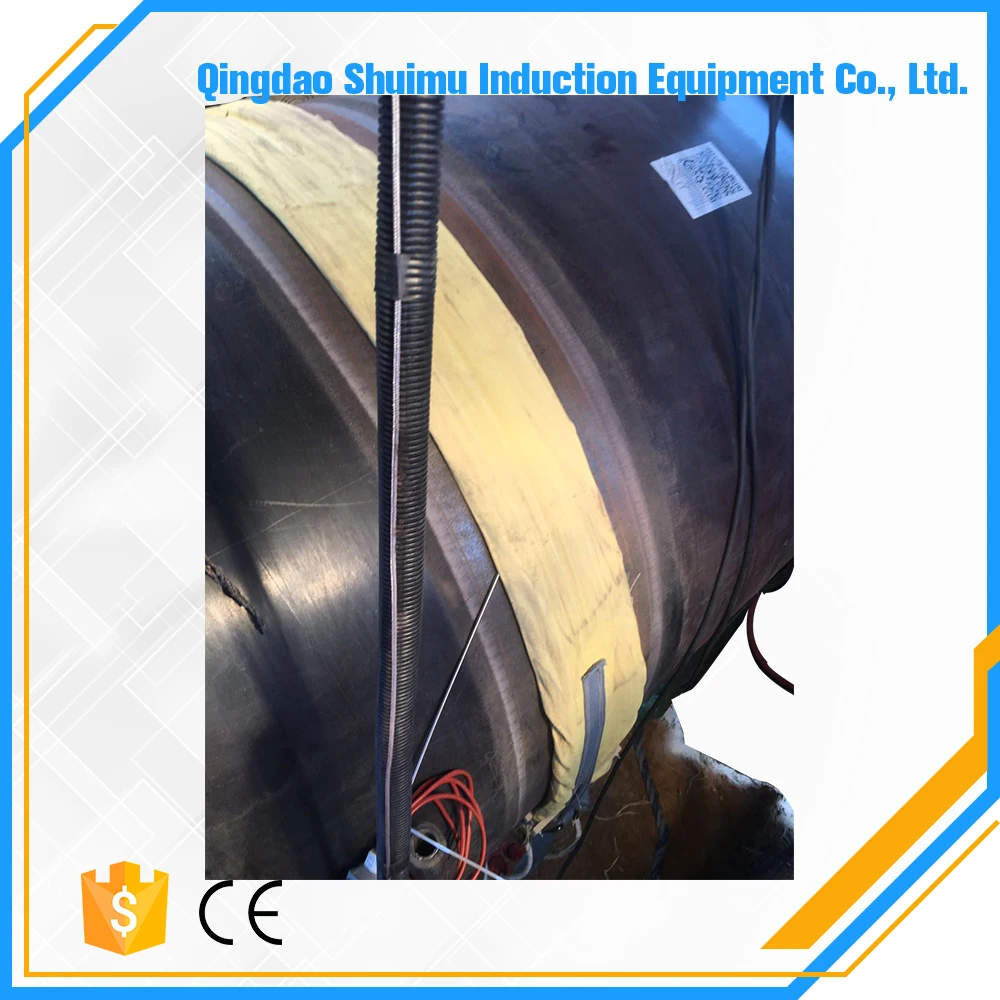

- WHT machine

- Ost weld heat treatment machine

- Induction pwht machine

- Weld preheat machine

- Induction p ost weld heat treatment machine

With push button control panels, the machines are exceptionally accessible and several high-end models supply you with the option to easily adjust for repeatable weld cycles, start, and weld crater. Choose a manufacturer with a proven track record in manufacturing heavy industrial equipment by using latest along with the most advanced fabrication welding techniques. A single gauge gas regulator calculates the pressure inside the bottle. A twin gauge measures the flow rate of the gas along with all the pressure. As the technology is developing drastically, different types of machines have introduced in market each one has their own qualities.

Many eBay sellers sell a complete batch of tig cups for what you might buy just one your local welding supply store. This means you must think about factors like the kind of metal you’ll be welding, how thick it’s, the location where the weld is going to be, the roughness with the material and how much time you have got open to spend on your welding. Filler materials are also available in different materials for example magnesium and tungsten. All the same, you may be required to visit several sites online to generate your welding equipment decision for the best deal at the right price.

Also, the welding industry ought to be equipped with modern tools including welding electrodes, welding torches, welding consumables and welding guns and really should follow the proper welding system with appropriate welding technology. A regular old arc welder will only be used as a last resort like whenever your mig welder breaks, but you will need one anyway simply because used arc welders are very inexpensive and you just might need one. One in the benefits of this type of Welding Equipment is that you are able to use it on thicker sheets of metal, as well as surfaces which might be rougher and unsuitable for welding with oxyacetylene equipment. However, a transformer based welding structure is usually expensive but tend to assist in a variety of applications.

Created at 2020-08-11 23:12

Back to posts

This post has no comments - be the first one!

UNDER MAINTENANCE